product description

Features of heat transfer oil double roller ironing machine:

● The super-large "mirror" φ415 six-slot ironing roller can be used, which has stronger penetration, higher ironing efficiency, and 30% increase in production efficiency. It is more suitable for polyester high-weight fabrics.

● The heat transfer speed of the thermal oil ironing roller is faster, the temperature is uniform, and the cloth surface effect is better.

● The temperature control is more precise, and the temperature difference between the rollers is controlled within ±2 degrees.

●Using touch screen control, 500 sets of process parameters can be automatically stored, and the output on duty, day and month can also be stored, and digital automatic production management can be fully realized. The widening device makes the feeding cloth more flat, without wrinkling, without crease, and without burn marks when ironing, and improve the yield.

●It can add automatic online function, high-efficiency spreading device, automatic deviation correction device, automatic stop device for broken cloth, automatic stop device for online hanging hammer, high degree of automation and reduced labor when running in continuous operation.

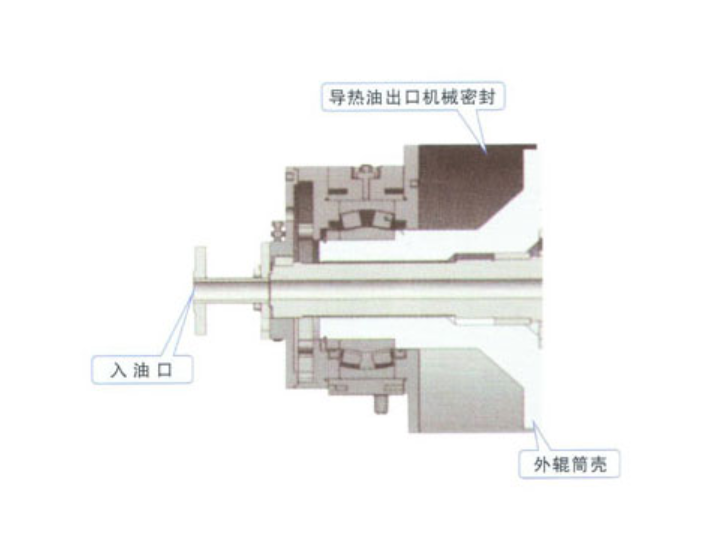

Heating principle of oil heating roller :

● Heating principle: coal combustion generates heat → heat transfer oil → heat transfer oil transport heat transfer oil distributor → heat energy → outer cylinder surface

● Comments: Adopting aerodynamic seals and oil circuit distributors, after more than five years of use by users, it has proved that the improvement is successful, energy saving, reliable at high speed, safe, uniform temperature, and maintains zero failure rate!

security issues:

● The new roller heat transfer oil is aerodynamically sealed and has an open design, so there is no internal pressure.

● Design without mechanical seal, the failure rate will be extremely low.

● The bearing is equipped with temperature detection to ensure maximum safety.

● The pipeline requires the installation of a one-way pneumatic valve. If any dangerous situation occurs, the heat transfer oil circuit will be cut off.

The Use Of Products And Main Technical Parameters

●Suitable for polishing of blankets, fake fur, woolen and other velvetfabrics, after polishing, the fabric surface will be more fluffy, soft andbright.

●Working width: 2000mm 2200mm 2500mm 2800mm

●Diameter of polishing roller: φ320mm φ370mm φ415mm

●Heating type: oil heating

●Surface temperature range of polishing roller : 5~250℃

●Difference in surface temperature of polishing roller: ±2℃

●Delivery speed : 5~6m/min , with inverters to adjust speed 。Weight : 5T

●Overall dimensions: ( length * width * height )4000* 4710*3170mm ( 2000mm)

4000*4910* 3170mm ( 2200mm)4000*5210*3170mm ( 2500mm)4000*5510* 3170mm ( 2800mm)

●Power requirement : voltage : 380v frequency : 50Hz